The night air hung thick with diesel fumes as the tow truck's floodlights carved jagged shadows across the mangled guardrail. What should have been a routine highway patrol had turned into a six-hour odyssey of hydraulic winches, shouted warnings, and the ever-present dread of 18 tons of steel deciding to finish its gravity-fueled descent into the ravine. This wasn't just any recovery operation—it was a dance with a 500-horsepower leviathan that had already demonstrated its contempt for the laws of physics.

They'd nicknamed the casualty "Big Blue" before the rotators even arrived—a reference to the cobalt-colored Freightliner Cascadia now lying on its side like a beached whale. The driver had walked away with nothing worse than bruised ribs and a shattered ego, which local EMTs attributed to the truck's reinforced cab and sheer dumb luck. "When rigs this size go over," remarked veteran recovery specialist Mark Kowalski, wiping grease from his safety goggles, "you don't expect to be peeling someone out of the wreckage. You expect to be collecting them."

The incident began predictably enough—an overloaded trailer taking a cloverleaf interchange too fast, the telltale screech of air brakes too late to counteract centrifugal force. What made this particular jackknife noteworthy was the cargo: thirty-two pallets of industrial marble slabs, each weighing nearly a metric ton. As the trailer swung wide, these became projectiles, shearing through tie-down straps like tissue paper. The resulting shift in weight distribution turned what might have been a simple skid into a slow-motion catastrophe.

Dawn revealed the true complexity of the recovery. Three cranes formed a tense equilateral triangle around the wreck, their cables singing under the strain. The marble slabs had to be removed individually using a forklift modified with custom clamps—a process requiring the precision of bomb disposal technicians. "One wrong tilt," explained site supervisor Elena Vasquez, her voice barely audible over the whine of pneumatic tools, "and those stones become guillotine blades. We're not just lifting a truck here. We're defusing a three-dimensional Jenga puzzle made of nightmares."

Environmental concerns added another layer of urgency. Diesel fuel glistened rainbow patterns in the runoff ditches, prompting the arrival of hazmat teams with absorbent booms. The location—less than a mile upstream from a protected wetland—meant every dropped wrench or misplaced bootprint carried potential regulatory consequences. "Nature doesn't care about our recovery timelines," noted EPA liaison James Worthy, watching as technicians scrambled to contain a minor hydraulic fluid leak. "That marshland has survived hurricanes and droughts. It won't tolerate our incompetence."

By midday, the operation attracted spectators. Truckers slowed their rigs to a crawl on the opposite lanes, some filming with phones, others making the universal gesture for "how the hell did that happen?" Local news helicopters circled like vultures until air traffic control rerouted them. Even the typically stoic state troopers paused their paperwork to watch the delicate ballet of chains and counterweights. The scene had taken on a perverse festival atmosphere, complete with snack vendors and teenagers taking selfies with the wreck in the background.

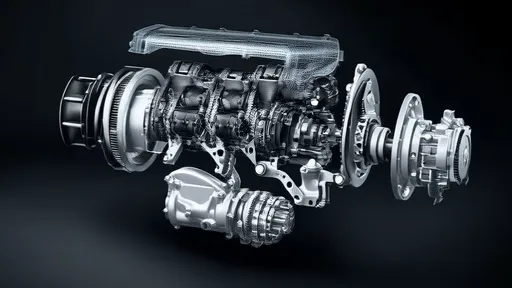

Modern trucking technology complicated the recovery in unexpected ways. The Cascadia's advanced aluminum alloy frame—designed to save weight and improve fuel efficiency—tended to crumple rather than break cleanly. "Older trucks," Kowalski mused while directing a cutting torch team, "had steel frames you could grab onto. This thing? It's like trying to lift a beer can after someone stepped on it." The truck's sophisticated computer systems also posed problems, with intermittent alarms blaring whenever rescue equipment disturbed some hidden sensor.

As shadows lengthened, the recovery team faced their final challenge: righting the cab without completing its destruction. This required synchronized lifts from two cranes while a third acted as stabilizer—a maneuver Vasquez compared to "performing brain surgery with construction equipment." When the truck finally settled onto its wheels with a ground-shaking thud, the cheer from exhausted workers drowned out even the diesel generators. The marble slabs would be a total loss, the trailer unsalvageable, but the $180,000 tractor lived to haul another day.

In the aftermath, investigators would pinpoint the root cause as a perfect storm of factors: an inexperienced driver pushing to meet a deadline, improperly secured cargo, and a notoriously tight curve that had claimed seventeen similar rigs in the past decade. The state transportation department promised renewed scrutiny of the intersection's design, while the trucking company announced mandatory cargo-securement retraining for all employees. None of which changed the visceral lesson etched into the guardrail's twisted metal: when dealing with forces this massive, complacency isn't just dangerous—it's an invitation for physics to demonstrate its cruelest sense of humor.

The final image—Big Blue being towed away at walking speed, its once-proud chrome grille now resembling a boxer's smashed smile—served as the day's fitting epitaph. Somewhere, a fleet manager was calculating insurance deductibles. Somewhere else, a factory waited for its marble delivery. And on a quiet stretch of highway, crews began the weeklong process of repairing barriers and scrubbing petroleum from rain gutters, their overalls stained with the unmistakable patina of hard-won experience.

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025